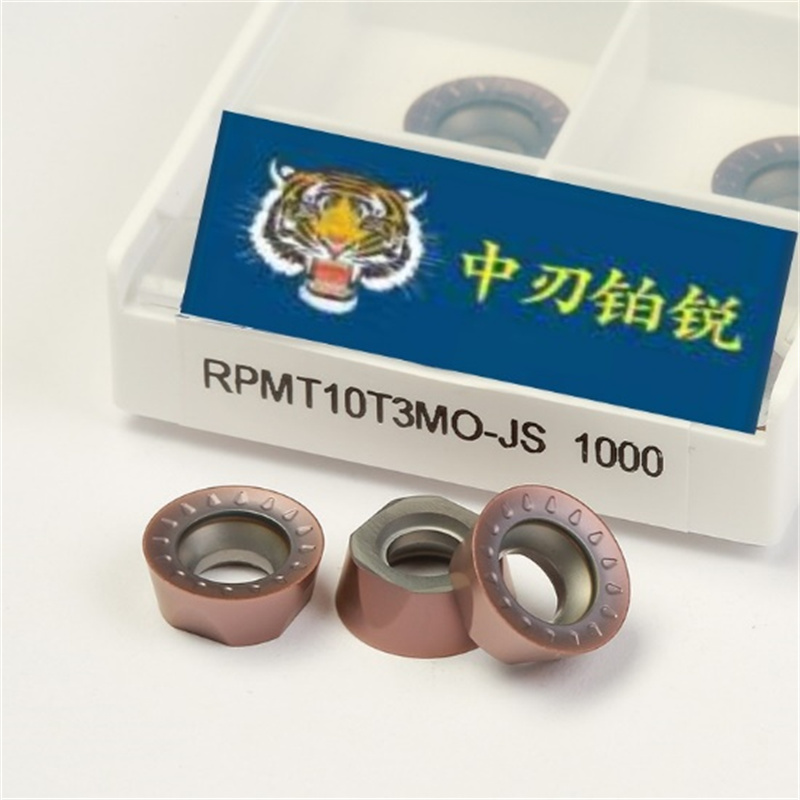

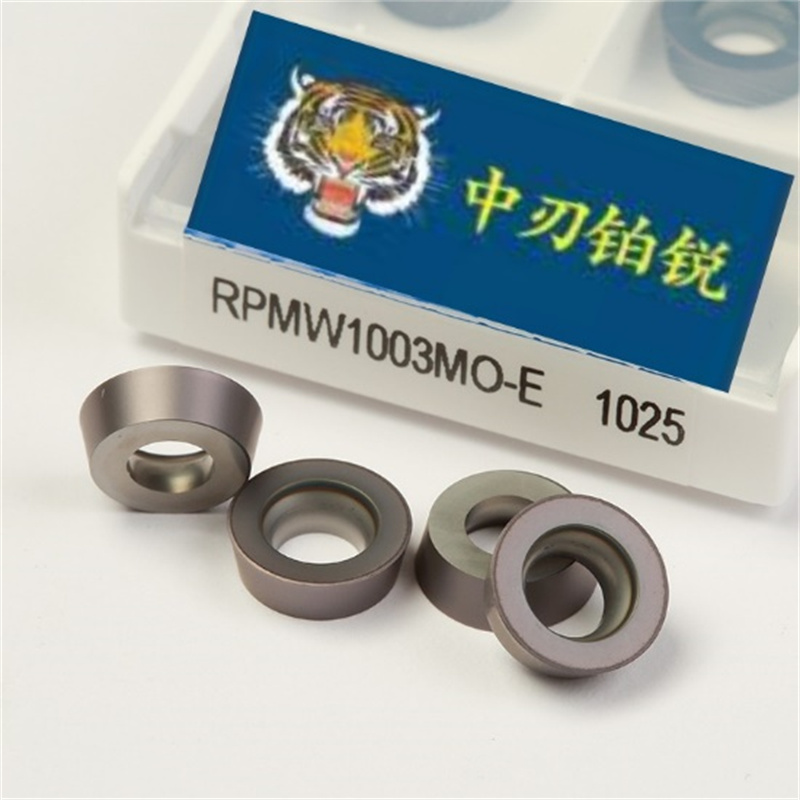

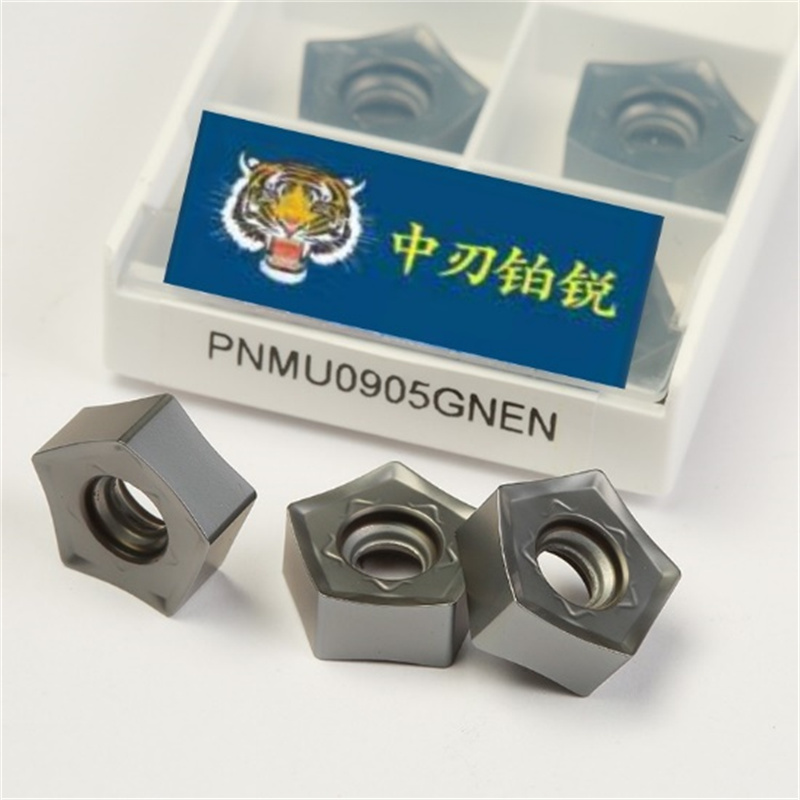

RPMT RDMW1204MO Indexable Milling Insert Carbide Insert Lathe Tools Face Face Milling Cutter

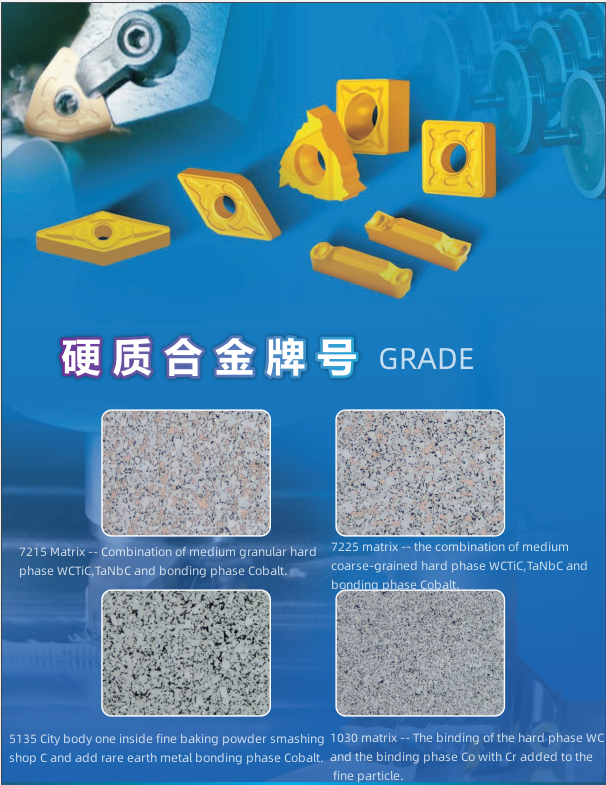

Material Grade Intshayelelo

Intshayelelo yezinto eziguqulayo intshayelelo:

I-7215 inamandla aphezulu kunye nokuqina kwe-matrix yokumelana netyhefu ephezulu, idityanisiwe

nge MT-TICN, AL2O3,TIN indibaniselwano ebalaseleyo inkqubo yokwaleka, kwaye ke

ngokusebenzisa i-coating advanced post-treatment ukuphelisa uxinzelelo lwangaphakathi lwe-blade layer, olulungele ukugqitywa kwentsimbi eqhelekileyo.

I-7125 edge yokhuseleko lwamandla aphezulu, ubunzima obuphezulu be-matrix edityaniswe ne-MT-TICN kunye nenkqubo yokugquma i-AL203, kwaye emva koko ngenkqubo yokugquma yasemva kokunyanga ukuphelisa uxinzelelo lwangaphakathi lokugquma, olulungele ukusetyenzwa okurhabaxa kwentsimbi eqhelekileyo, ukugqiba isiqingatha kunye nokugqiba. inxalenye yeemfuno ze-workpiece yoburhabaxa azikho ukugqiba okuphezulu.

I-4025 yokumelana nomhlwa okuphezulu, kwaye ngenkqubo ethile yoxinzelelo lwe-matrix yamandla aphezulu kunye ne-MT-TICN kunye ne-AL2O3 etyebileyo yokwaleka indibaniselwano egqwesileyo, kunye netekhnoloji yokwaleka yasemva konyango lokufumana umphezulu ogudileyo wokugquma, olungele umatshini orhabaxa, ukugqiba isiqingatha. kunye nokugqitywa kwentsimbi.

I-1030 ingqolowa ecolekileyo, ukuchasana noguquko olugqwesileyo kunye nenkqubo yoxinzelelo lwe-sintering ukuze ufumane amandla aphezulu kunye nokumelana ne-matrix yokumelana, kunye nenkqubo yokugquma i-nano PVD, kwaye emva koko ngenkqubo yokugquma yasemva konyango lokufumana umphezulu ogudileyo wokugquma, olungele ukugqitywa kwentsimbi eqhelekileyo, intsimbi ecinyiweyo, intsimbi ecwecwe ngechromium kunye nentsimbi engatyiwayo yokugqiba kunye nokugqiba.

I-1120 i-ultra-fine grain, i-deformation resistant egqwesileyo, kunye nenkqubo yoxinzelelo lwe-sintering ukuze ufumane amandla aphezulu kunye ne-matrix yokumelana nokunxiba, kunye ne-nano SI equlethe inkqubo yokugquma i-PVD, emva kokuhamba phambili kokutyalwa emva konyango ukuze ufumane indawo egudileyo yokugquma.Ifanelekile i-grooving kunye nokusika intsimbi eqhelekileyo, intsimbi eqinile kunye nentsimbi.

Ukuqaliswa kwezinto zokugaya kunye nokugaya

I-1030 ye-NC-TIALN yokugqoka idibaniswe kunye ne-matrix eqinile kunye ne-ductile yeengqungquthela ezintle zifanelekile ukugaya i-coarse kunye ne-semi-finished yazo zonke iintlobo zezinto ezicutshungulwayo.I-grooving, ukusika kunye nokugrunjwa kwe-half aperture.

I-1130 NC-TIALN yokugqoka equkethe i-SI idibaniswe kunye neengqungquthela ezintle kunye nokuqina okulungileyo kwe-matrix ye-alloy enzima, ifanelekile kwinsimbi engenasici, isigaba sentsimbi kunye ne-semi-finish kwi-processing, ukufezekisa indibaniselwano egqibeleleyo yokhuseleko kunye nokumelana nokugqoka.

I-5035 eyongeziweyo yokunxiba kunye nezinto zokumelana nobushushu obuphezulu be-CVD yokwambathisa, ubulukhuni bokugquma okuphezulu kunye nokumelana nobushushu obuphezulu ukubonelela ngokhuseleko olusebenzayo kumphetho wokusika, itekhnoloji ekhethekileyo yonyango, ukugquma kunye ne-matrix ngokuqinileyo, ilungele i-alloy ephezulu yobushushu, i-titanium alloy materials ichanekile. ukusetyenzwa kokugaya.

I-5135 i-NC-TIALN yokugqoka equkethe i-SI edibeneyo kunye ne-matrix ye-carbide kunye nokuqina kwempembelelo egqwesileyo, ifanelekile kwiindawo zetsimbi, insimbi engenasici, i-grooving, ukusika ukusika okunzulu, ukuqhutyelwa kokutya okukhawulezayo kunye ne-aperture drilling processing.

Isicelo

Usetyenziso Olungundoqo:Ukucutshungulwa kwentsimbi yekhabhoni, intsimbi ephoswe ngentsimbi, insimbi engenasici

Kubunzima obahlukeneyo bomsebenzi womngundo, sinokubuvavanya ngokuchanekileyo ubomi bezixhobo zokusika.Ubuchwephesha bokugaya intsimbi okanye intsimbi yokusila okanye intsimbi yokusila okanye i-aluminium alloy, ukufakwa kwethu kokugaya kwenziwa ngokukodwa kumhlaba osemgangathweni we-ultra-fine carbide, kunye ne-thinnest AlTiN high Al-coating technology.Ezi zenza ukuba i-Milling cutter yethu ibe nesiphumo esifanelekileyo sokusebenza kunye nomgangatho ozinzileyo ukuya kowona aphezulu.

IiNkcazo zeMveliso

| Uhlobo | Ubungakanani(mm) | ||

| D | S | D1 | |

| RDMW120400-PR | 12.00 | 4.76 | 4.40 |

| RDMW1204MOT-PM | 12.00 | 4.76 | 4.40 |

| RDMW1204MO-TT | 12.00 | 4.76 | 4.40 |

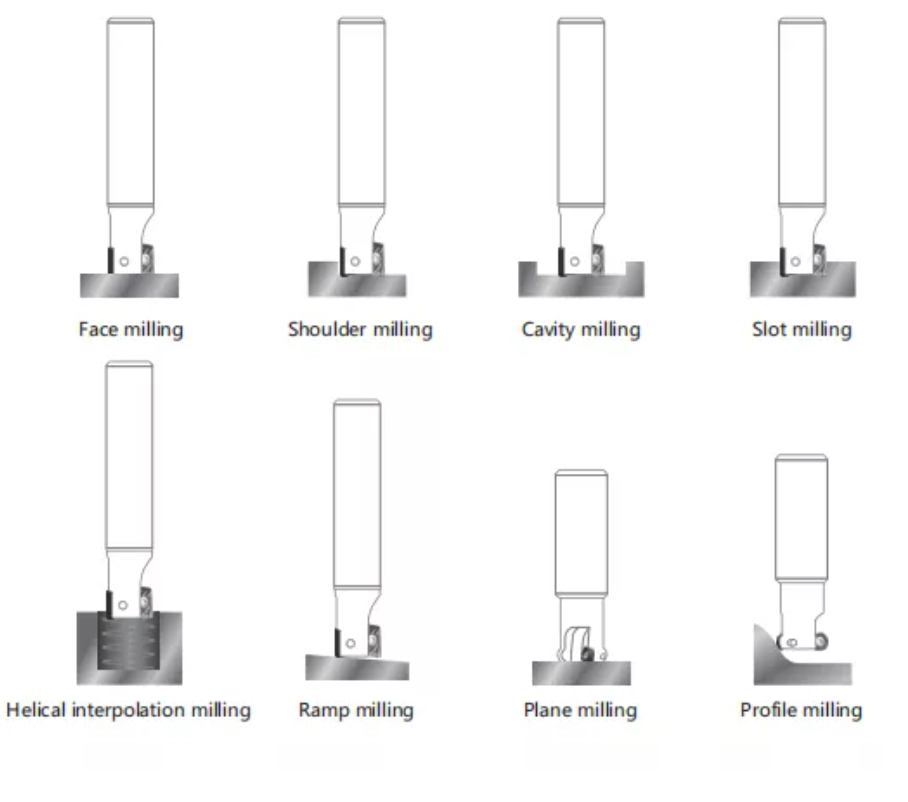

Nokuba ufuna ukugaya ngokubanzi okanye ukufakwa kobunzima bokugaya ubuso, ukugaya amagxa, ukugaya i-slot, ukugaya iprofayili, okanye ukugaya i-ramp, okanye ukugaya iimfuno eziphezulu zokugudiswa komphezulu, injineli yethu inokuguqula uyilo lwakho lube yinto yokusila ngeentsuku nje.

Isiboniso sokugquma

Izatifikethi

Izixhobo zeMveliso

Izixhobo ze-QC

Inkonzo yethu

Inkonzo yokuthengisa kwangaphambili:

Sinabasebenzi bokuthengisa abaqeqeshiweyo, abanokwazi iinkcukacha malunga neemfuno zakho kwaye banikeze impendulo.

Inkonzo yoThengiso:

Emva kokusayinwa kwekhontrakthi, abasebenzi bethu bokuthengisa abaqeqeshiweyo baya kunxibelelana kwaye basebenze kwiishedyuli zemveliso okanye utshintsho lwakho lwemfuno.

Inkonzo yasemva kwentengiso:

Siza kulungiselela ukubuyiswa kunye nokutshintshwa kweemveliso ngexesha elifanelekileyo ukuba zineengxaki zomgangatho.Kwangaxeshanye, utyelelo lokubuyela luya kwenziwa rhoqo ukwazi imeko yenkonzo yeemveliso zethu.