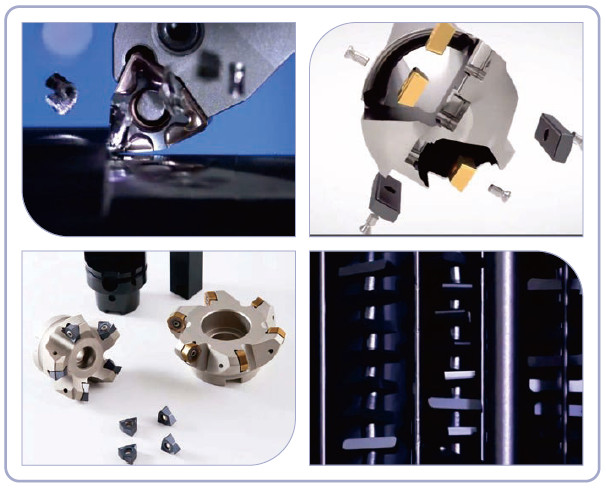

Inkqubo yokusika ithatha malunga ne-90% yomsebenzi womatshini.Isixhobo "izinyo" zesixhobo somatshini woshishino, esichaphazela ngokuthe ngqo inqanaba lokucubungula kwishishini lokuvelisa.Ukusika kubhekisela ekusikeni kwezinto ezigqithisileyo ukusuka kumphezulu womsebenzi, ukuqinisekisa ukuba i-workpiece yejometri, ukuchaneka komgangatho, umgangatho ophezulu kunye neminye imiba yeemfuno zoyilo lwendlela yokwenza, i-accounting malunga ne-90% yomthwalo wonke womsebenzi womatshini.Ukusika ngokuqhelekileyo kufezekiswa ngokusika izixhobo zoomatshini, kwaye isixhobo sisona sixhobo sisisiseko esisetyenziswayo, njengoko "amazinyo" ezixhobo zoomatshini boshishino, umgangatho walo uchaphazela ngokuthe ngqo ukuveliswa komgangatho wobugcisa bokuvelisa oomatshini, ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.Izixhobo zokusika zinyuka zinyuka kubaboneleli bempahla ekrwada, emazantsi omlambo asetyenziswa kumashishini amakhulu okuvelisa.Thatha isixhobo se-carbide esixhaphakileyo njengomzekelo, ngokwezinto ezicutshungulwayo zinokwahlulwa zibe: intsimbi, insimbi engenasici, intsimbi, isinyithi esingenantsimbi, i-alloy-resistant-resistant alloy, insimbi eqinile, njl. i-tungsten carbide, i-cobalt powder, isisombululo esiqinileyo se-tantalum niobium, njl.) zomkhosi, oomatshini zonyango kunye nezinye iindawo zikwabonelela ngesicelo sobugcisa esibanzi kunye nendawo yokuguqula izixhobo ze-carbide.

Ziziphi iimpawu zezixhobo zokusika i-carbide?

I-1.ubunzima obukhulu: Isixhobo se-Carbide senziwe nge-carbide enobunzima obuphezulu kunye nenqanaba lokunyibilika (eyaziwa ngokuba yinqanaba elinzima) kunye ne-binder yensimbi (eyaziwa ngokuba yi-binding phase) nge-powder metallurgy method, ubunzima bayo bu-89 ~ 93HRA, buphezulu kakhulu kunesantya esiphezulu sensimbi. , kwi-5400C, ubunzima busenokufikelela kwi-82 ~ 87HRA, kunye nesantya esiphezulu sobushushu begumbi lentsimbi (83 ~ 86HRA) efanayo.

2. Amandla okugoba kunye nokuqina: amandla okugoba e-alloy eqinile eqhelekileyo akuluhlu lwe-900 ~ 1500MPa.Ukuphakama komxholo wesigaba sokubopha isinyithi, ukuphakama kwamandla okugoba.Xa umxholo wesibophelelo ufana, YG(WC-Co).Amandla e-alloy aphezulu kune-YT (WC-Tic-Co) i-alloy, kwaye amandla ayancipha ngokunyuka komxholo we-TiC.I-Hard alloy luhlobo lwemathiriyeli enqabileyo, ukuqina kwayo kwempembelelo kwiqondo lobushushu begumbi yi-1/30 ~ 1/8 ye-HSS kuphela.

3. Ukumelana nokunxiba kakuhle.Isantya sokusika isixhobo se-carbide si-4 ~ 7 amaxesha aphakamileyo ngaphezu kwesantya esiphezulu sensimbi, kwaye ubomi besixhobo bu-5 ~ 80 ngamaxesha aphezulu.Ukuvelisa i-mold, izixhobo zokulinganisa, ubomi kune-alloy tool yensimbi 20 ~ 150 amaxesha aphezulu.Unokusika i-50HRC okanye izinto ezinzima kakhulu.

Ixesha lokuposa: Dec-29-2022